Fiber lasers unique tools for automotive & aerospace manufacturing Laser Technology Research

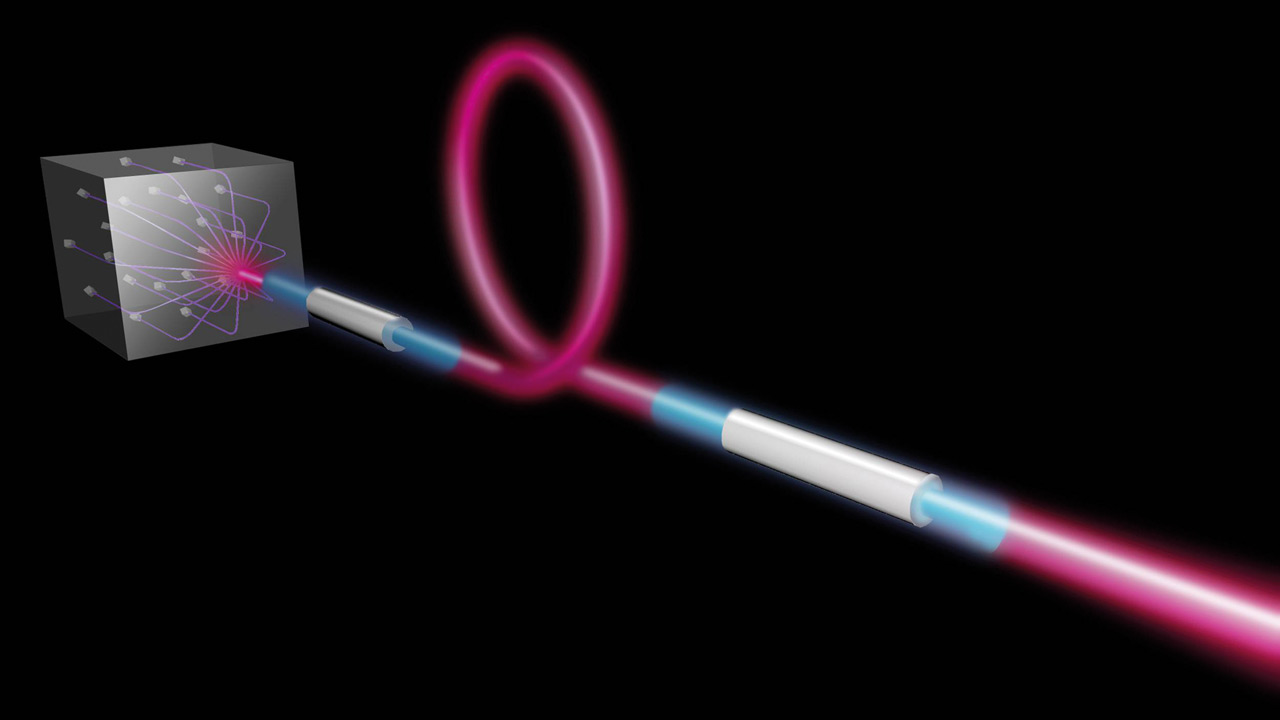

What Is a Fiber Laser? A fiber laser can be defined as a solid-state laser that makes use of optical fibers as its active gain medium. A fiber made of glass silicate or phosphate absorbs unprocessed light from the pump laser diodes and converts it into a concentrated beam of a certain wavelength.

Fiber laser cutting machine FOL3015AJ Description

Fiber lasers use an optical fiber cable made of silica glass to guide light. The resulting laser beam is more precise than with other types of lasers because it is straighter and smaller. They also have a small footprint, good electrical efficiency, low maintenance and low operating costs.

6 Things You Need To Know Before Using A Fiber Laser Marking Machine Richannel

Laser light - a special wave If you've ever seen a laser pointer projecting a spot onto a screen, you'll realise that a laser beam looks like nothing else. Laser beams usually have the following unusual properties: Highly collimated - the beam is close to straight A single frequency or colour

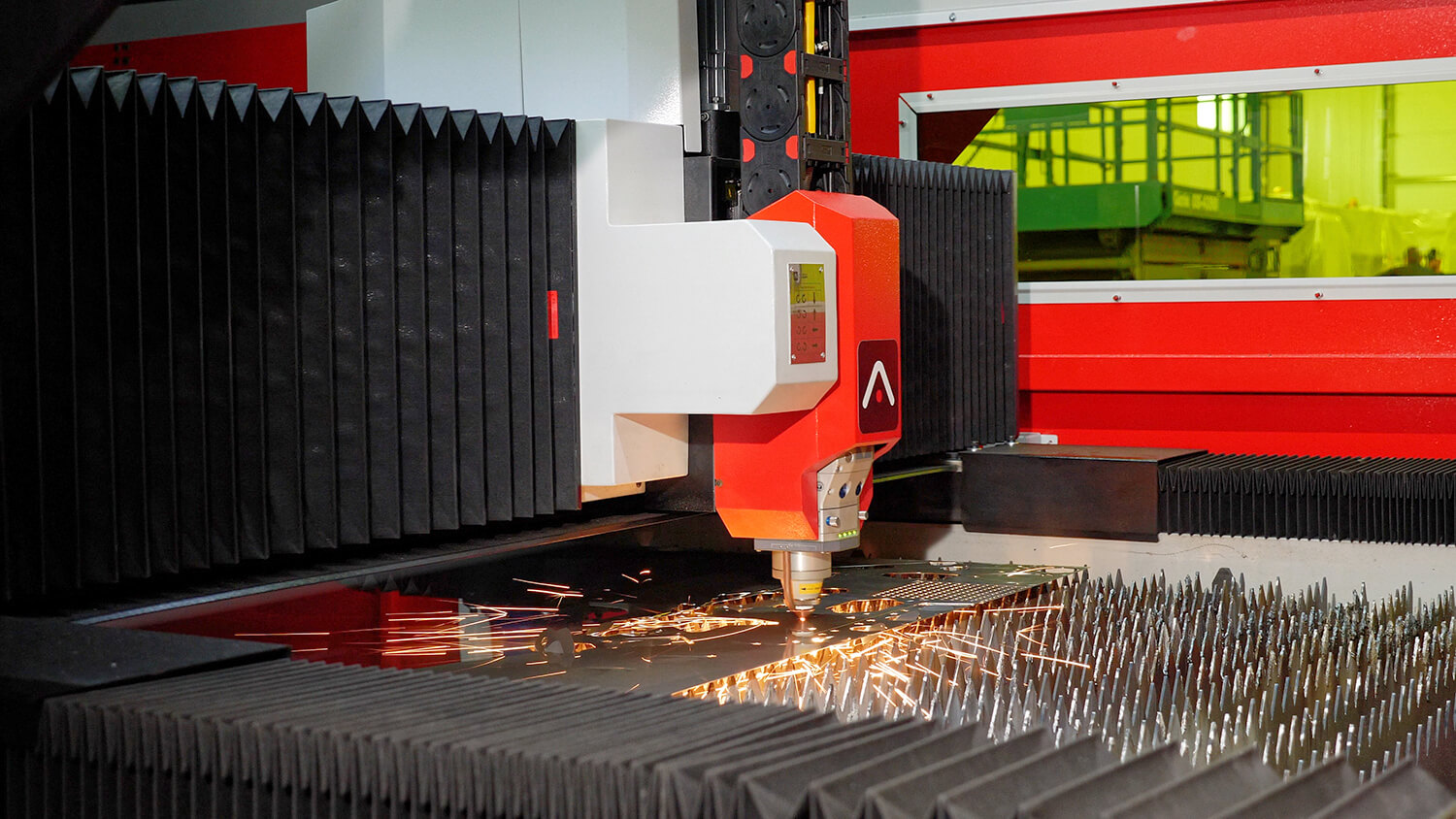

HOW MUCH GAS & WHAT TYPES OF GAS DOES A FIBER LASER USE? Fiber Laser CNC Cutting Machines

A fiber laser (or fibre laser in Commonwealth English) is a laser in which the active gain medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium and holmium. They are related to doped fiber amplifiers, which provide light amplification without lasing .

fiber laser marking heatsign

Fiber Lasers: A Beginner's Guide Braden Todd, Glassmith2, explores the technology of fiber lasers. Matt Dixon November 15, 2018 7 minute read Recently, I took on the daunting task of figuring out if Glassmith2, my business based in Boulder, Colorado, should add a fiber laser, and what all features we needed that fiber laser to have.

The Best Fiber Laser Engraver You Should Buy in 2023 OMG Laser

HOW A FIBER LASER WORKS KEY COMPONENTS USED TO BUILD A FIBER LASER DOPED OPTICAL FIBER DOUBLE CLAD FIBER YTERRBIUM (Yb) DOPANT PUMP LASER DIODES PUMP LASER COMBINERS FIBER BRAGG GRATINGS FIBER LASER WAVELENGTHS RESOURCES & FURTHER READING Fiber Laser Diagram DEFINITION (CONTINUED):

Lazer Metal Kesim Makinası FİBER LASER

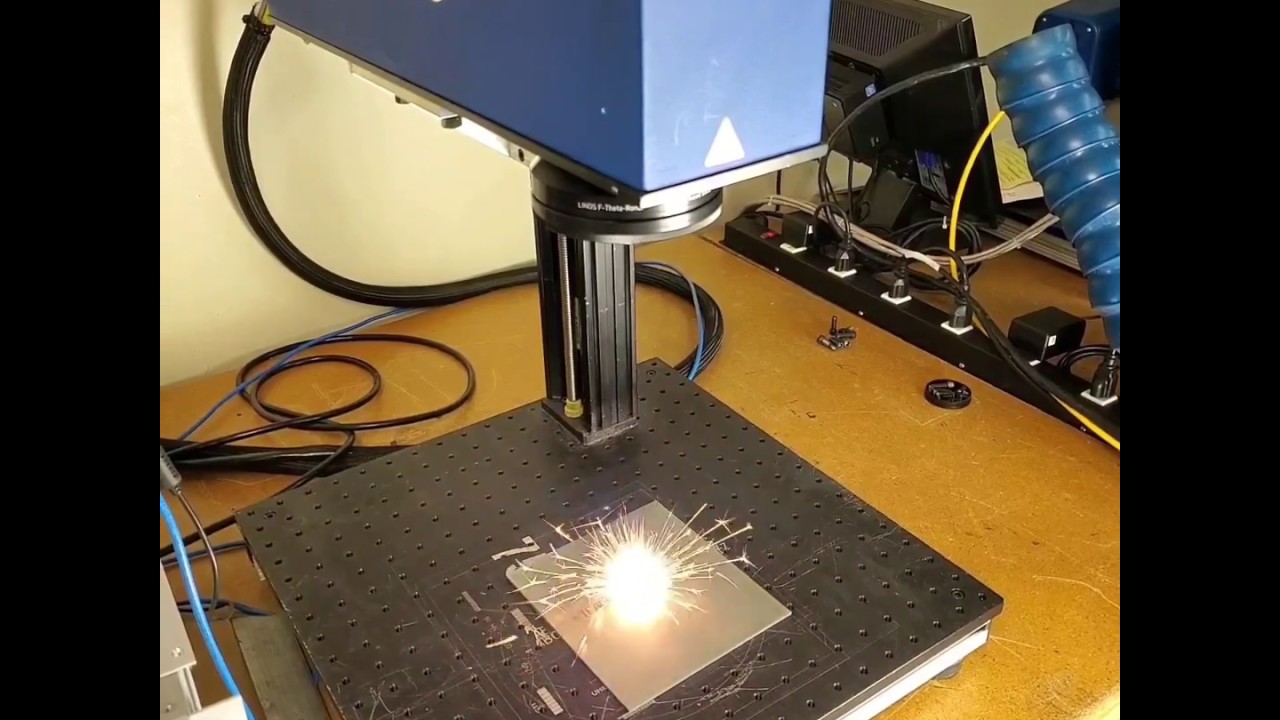

FIBER LASER ENGRAVING STAINLESS STEEL HOW TO Roger Webb 298K subscribers Subscribe Subscribed 22K views 2 years ago From the Laser lab, a Roger Clyde Webb easy Laser learning tutorial Video.

fiber laser More Photonics

What Is Fiber Laser Cutting. Fiber Laser Cutting is a hot cutting method that utilizes a focused high-power density laser beam as the main heat source. This causes the irradiated materials to rapidly melt, evaporate, ablate, or reach ignition point. At the same time, the use of high-speed airflow that is coaxial with the laser beam helps blow away the molten material, enabling cutting of the.

Tubes Fiber Laser

Building a FIBER LASER!!! Learn2Laser 2.82K subscribers Subscribe 10K views 1 year ago Follow along as I attempt to build my first PC and fiber laser! In this video I finish building the PC.

State of the Art Technology 12 Advantages of Fiber Laser Systems

Our galvo laser is definitely the right tool for these jobs! As I mentioned in my first article (Fiber Lasers: A Beginner's Guide, September page 28), a major factor in my purchase decision was that Radian's galvo lasers have a 3-D option for the engraving. This option isn't just for carving a 3-D design, but rather to engrave around 3-D.

Is Fiber Laser Cutting the Right Solution for Your Application?

The fiber laser source generates laser light by pumping intense diode light into fiber optics cables that are doped with the rare-earth element, ytterbium (Yb3+), which is referred to as the medium or gain medium As

Fiber Laser

Fiber lasers: this tutorial provides an overview of the technical approaches most commonly used to make a fiber laser. It explains the component choices and various architectures that are generally used for CW or pulsed fiber laser development. I. Fiber lasers principles: A fiber laser is a laser in which the amplifying media is an optical fiber.

Applications of fiber laser in medical sector Laser metal cutting machine Manufacturers

January 9, 2023 at 7:00 am Tubular laser beams can create what amount to fiber-optic cables made of thin air, researchers report in a study to appear in Physical Review X. Laser-heated air.

The fiber laser marking process is increasingly popular for numerous uses. Its high

3) The fiber laser can operate under harsh conditions, such as high impact, high vibration, high temperature, and dusty conditions. 4) Due to the excellent flexibility of the fiber, the laser can be designed to be quite small and flexible, with a compact shape and small volume, making it easy for system integration and offering a high performance-price ratio.

Safety Tips To Remember When Using a Fiber Laser

These laser parameters have been tested mostly with our BCF power laser source, but they can also be applied to other power laser sources in the market. Understand that the result on your material can be different from the result shown in the videos.

Laser Fiber ubicaciondepersonas.cdmx.gob.mx

Laser Marking: A MOPA fiber laser can create different colors on metals and plastics by changing the laser beam properties.; Color Filling: You can paint the engraved areas manually with a brush or spray paint.You can use masking tape or toilet paper to clean the surface. Color Powder: You can use powder paint to create colorful engravings.You need to scatter the powder and melt it with the laser.